Precision and efficiency are essential in the world of stone cutting, especially for American contractors who often manage complex projects with tight deadlines. Whether working on residential kitchens, commercial lobbies, or custom architectural features, contractors need tools that deliver consistent results. For those searching for solutions to streamline their workflow and improve accuracy, the bridge saw stands out as a game-changer in modern stone fabrication.

Advancing Precision and Consistency

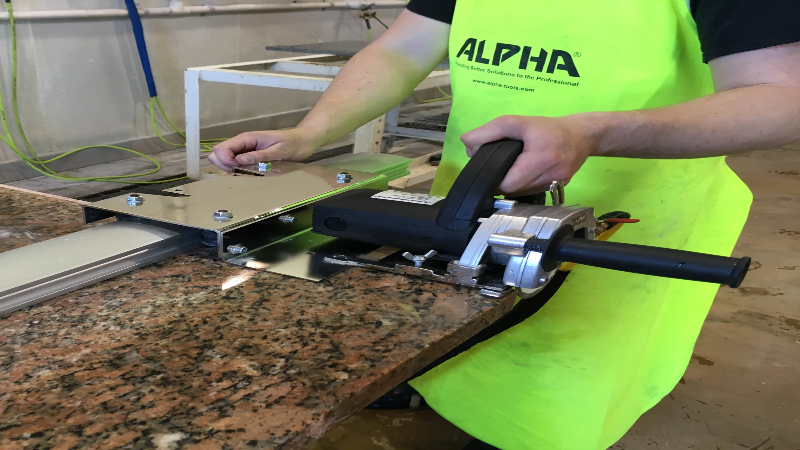

One of the most significant advantages of using a bridge saw is its ability to deliver precise and repeatable cuts. Unlike handheld tools, which can introduce inconsistencies and human error, a bridge saw operates along a guided rail system. This setup enables straight, clean cuts through various types of stone, including granite, marble, and quartz. As a result, contractors can achieve tight seams and flawless edges, which are crucial for high-end installations. The automated movement also reduces the likelihood of costly mistakes, helping to maintain material integrity and minimize waste.

Increasing Efficiency and Productivity

Time is money in the contracting business, and bridge saws are designed to maximize both. These machines are equipped to handle large slabs, allowing contractors to process more material in less time compared to manual methods. Many models offer programmable cutting patterns, which means repetitive tasks can be completed with minimal supervision. This automation not only speeds up production but also frees up skilled labor for other critical tasks on the job site. The reduction in manual labor translates to fewer workplace injuries and a more streamlined workflow overall.

Key Benefits for Contractors

• Enhanced Accuracy: Guided rails ensure straight, uniform cuts every time.

• Material Versatility: Suitable for a wide range of natural and engineered stones.

• Reduced Waste: Precision cutting minimizes off-cuts and material loss.

• Labor Savings: Automation reduces the need for constant manual oversight.

• Improved Safety: Less manual handling lowers the risk of accidents and repetitive strain injuries.

Adapting to Modern Project Demands

Today’s construction and remodeling projects often feature intricate designs and custom stonework. Bridge saws are equipped with features that cater to these needs, such as adjustable cutting angles, water-cooled blades to reduce dust and heat, and digital controls for complex patterns. This versatility allows contractors to take on a broader range of projects, from countertops and flooring to decorative wall panels and outdoor features. With the ability to switch between different materials and thicknesses seamlessly, contractors can meet client expectations while maintaining high standards of craftsmanship.

Maximizing Return on Investment

Investing in advanced equipment like a bridge saw is a strategic decision for American contractors looking to stay competitive. The upfront cost is quickly offset by the savings in labor, reduced material waste, and the ability to take on more sophisticated projects. Additionally, the reputation for quality work that comes with precision stone cutting can lead to more referrals and repeat business, further enhancing profitability.

In summary, adopting a bridge saw transforms the way American contractors approach stone-cutting projects. By combining accuracy, efficiency, and adaptability, this tool enables professionals to deliver superior results on time and within budget. As the demand for precision and customization in stonework continues to grow, integrating a bridge saw into the workflow is a smart move for contractors aiming to set themselves apart in a competitive market.